Description

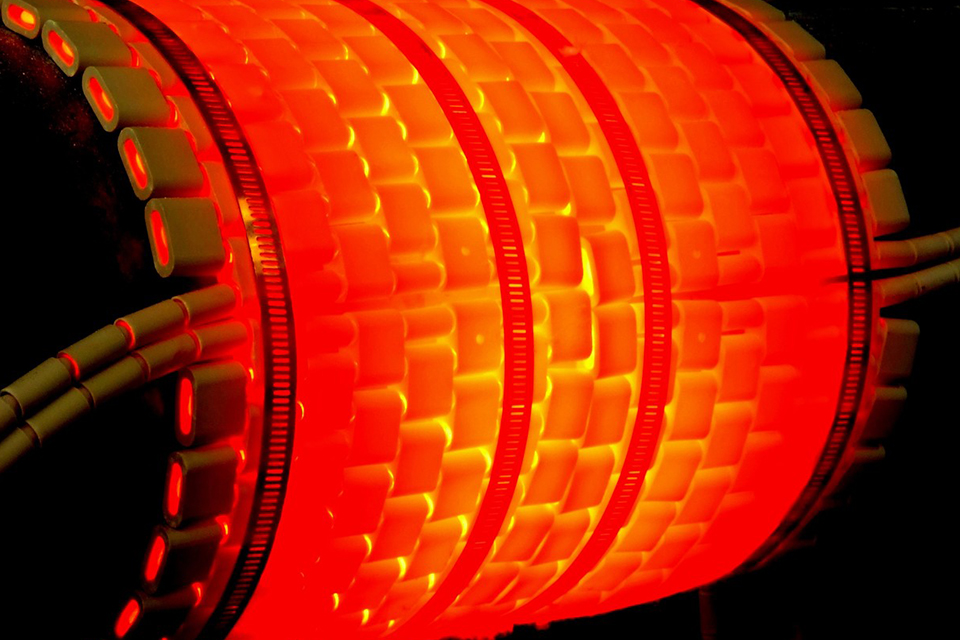

Heat treatment is a controlled process used to alter the microstructure and properties of metals and alloys. It involves heating and cooling metals to specific temperatures to achieve desired characteristics, such as increased strength, toughness, or resistance to corrosion.

Our Heat Treatment services ensure that your materials meet the required specifications, improving their performance, reliability, and lifespan.

What We Provide

- Post Weld Heat Treatment (PWHT) of pipe works

- Controlled Pre Heat : Conventional method(Pad heating) & Coil heating

- PWHT of Fabricated pipe spools using 12m x 2.4m x 2.4m Permanent electrical furnace

- Various types of permanent and temporary furnaces for pipings and various vessels

- PWHT of various equipment like Vessels, Heat Exchangers, Columns etc. using temporary erected furnace Using Electrical, Gas or Oil firing

- Refractory Dry Out

- Normalizing

- Quenching

- Solution Annealing

Benefits

- Improved strength and toughness

- Enhanced corrosion resistance

- Increased ductility and formability

- Reduced risk of cracking and failure

- Improved weld quality and integrity

- Enhanced overall performance and lifespan of the material